THE Australian Transport Safety Bureau (ATSB) has released its report into an emergency landing at Newcastle Airport earlier this year involving a light aircraft.

On 13 May, a Beechcraft King Air B200 departed Williamtown Airport on a charter flight to Lord Howe Island via Port Macquarie, with a pilot and two passengers onboard.

Advertise with News of The Area today.

Advertise with News of The Area today.It’s worth it for your business.

Message us.

Phone us – (02) 4981 8882.

Email us – media@newsofthearea.com.au

As the pilot retracted the landing gear during the initial climb, mechanical crunching noises were heard, and the pilot saw that the red indicator lights on the landing gear control handle remained illuminated.

An air traffic controller visually confirmed that the nose landing gear was only partially retracted.

“Unable to extend the gear following emergency extension procedures, the pilot held for approximately four hours to burn fuel, before conducting a wheels-up landing at Williamtown with emergency services standing by,” ATSB Director Transport Safety Stuart Macleod said.

Many Port Stephens residents reported seeing the King Air during the pilot’s efforts to reduce the weight and danger to the aircraft and persons on board.

Once cleared by Air Traffic to land, the pilot conducted what was described by both civilian and RAAF personnel at the airport as a “textbook wheels-up emergency landing”.

The aircraft sustained minor damage, but the pilot and passengers walked away uninjured.

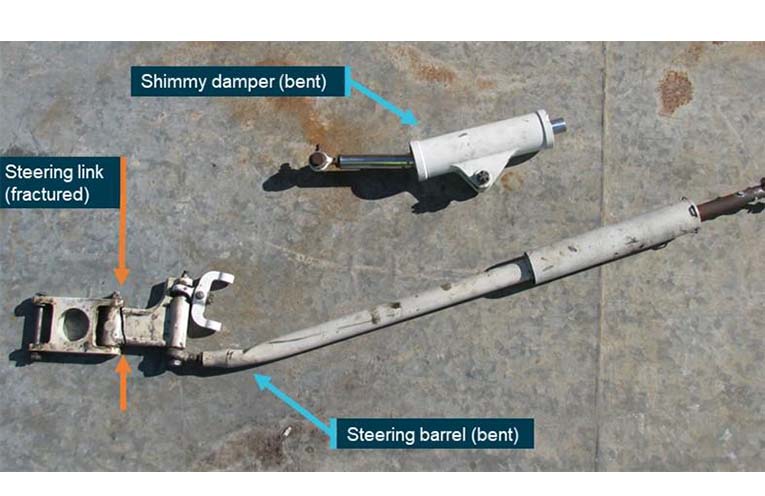

“Detailed examination of the steering link at the ATSB’s technical facilities in Canberra, including with the use of a scanning electron microscope, identified a pre-existing fatigue crack on the fracture surface, which had initiated from a surface flaw,” Mr Macleod explained.

“When the steering link fractured, either during take-off or the gear retraction sequence, the nose wheel was able to rotate beyond its normal operational limits, and a significant left rotation led the nose gear shimmy damper to become jammed against a door hinge within the nose wheel well.”

During the course of the investigation, the aircraft manufacturer advised the ATSB that it was not aware of other instances of this specific malfunction, and nor did a review of the ATSB database identify any similar occurrences involving King Airs.

“Nonetheless, King Air B200 operators and maintainers should be aware that while scheduled maintenance inspections require general inspection of the nose wheel steering parts, they do not call for a detailed inspection for cracks – such as the one which precipitated this failure,” Mr Macleod said.

The incident highlights the value of aircraft system knowledge, and resource management in resolving malfunctions and in-flight emergencies, Mr Macleod observed.

“The pilot managed fuel considerations to reduce the risk of fire, engaged company personnel and air traffic control for assistance, liaised with emergency services and prepared the passengers for the wheels-up landing, minimising the risk of injury and ensuring the evacuation was conducted safely.”

The full report can be found on the ATSB website at https://www.atsb.gov.au/publications/investigation_reports/2024/report/ao-2024-031

By Simon EKINS